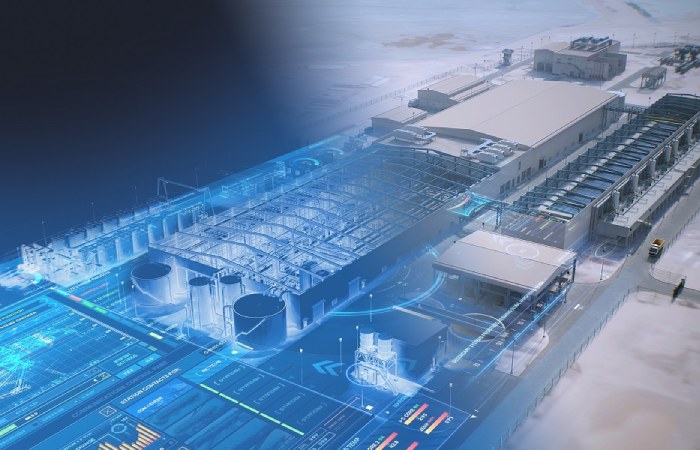

Digital twin technology transforms industries by providing virtual replicas of physical assets, systems, and processes. These digital twins services offer valuable insights and enable better decision-making. Let’s explore the key features of effective digital twin solutions.

Real-Time Data Integration

One of the most important features of digital twin solutions is real-time data integration. This involves collecting data from sensors and other sources in real time and feeding it into the digital twin. This continuous data stream ensures that the digital twin is always up-to-date and accurately reflects the current state of the physical asset.

Real-time data integration allows companies to make informed decisions quickly. For example, if equipment shows signs of wear, the digital twin can alert maintenance teams immediately, preventing costly breakdowns. This proactive approach helps maintain operational efficiency and reduces downtime.

Predictive Analytics

Effective digital twin solutions use predictive analytics to forecast future performance and identify potential issues before they occur. By analyzing historical and real-time data, predictive models can anticipate equipment failures, optimize maintenance schedules, and improve overall asset management.

Predictive analytics also help in optimizing processes. For instance, in manufacturing, digital twins can simulate production line changes and predict their impact on efficiency and output. This allows companies to implement improvements without disrupting operations, leading to better productivity and cost savings. Predictive analytics can enhance safety by identifying potential hazards before they become critical.

Enhanced Visualization

Visualization is a crucial aspect of digital twin solutions. Advanced visualization tools create detailed 3D models of physical assets, making it easier for users to understand and interact with the digital twin. These models can be viewed from different angles and levels of detail, providing a comprehensive understanding of the asset’s condition and performance.

Enhanced visualization also helps in training and simulation. For example, technicians can use virtual reality (VR) to practice complex maintenance tasks on the digital twin before performing them on the equipment. This reduces the risk of errors and enhances skill development.

Additionally, enhanced visualization can facilitate better communication among teams. Engineers, operators, and managers can all view and discuss the same 3D model, ensuring everyone is on the same page and improving collaborative decision-making.

Interoperability

Interoperability is essential for effective digital twin solutions. Digital twins must integrate seamlessly with various systems and platforms within an organization. This includes compatibility with existing software, hardware, and communication protocols to ensure smooth data exchange and functionality.

Interoperability also extends to external systems. For example, digital twins in smart cities must interact with different infrastructure components, such as traffic lights, energy grids, and public transportation systems. This interconnectedness enables comprehensive management and optimization of urban environments.

Interoperability ensures that digital twin solutions can evolve with technological advancements. As new technologies emerge, interoperable digital twins can integrate these innovations without significant reconfiguration.

Scalability

Scalability is a key feature that determines the long-term effectiveness of digital twin solutions. As businesses grow and their operations expand, digital twin solutions must be able to scale accordingly. This includes handling increased data volumes, integrating additional assets, and supporting more complex analyses.

Digital twins services are revolutionizing businesses’ operations by providing real-time data integration, advanced analytics, interoperability, scalability, and enhanced visualization. These features enable companies to make better decisions, optimize operations, and predict future outcomes. As digital twin technology continues to evolve, its impact across various industries will grow, offering new opportunities for innovation and efficiency.